Technology Platform

Since 2014, Yeasen has established six core technology platforms. 1. ZymeEditor™ Protein Directed Evolution and Rational Design Platform. 2. HiSpecif™ Highly Specific Antibody and Recombintant Protein Platform. 3. High Density Protein Fermentation & Ultra-clean Protein Purification Platform. 4. NGS Library Preparation R&D Platform. 5. Molecular Diagnostic Reagent R&D Platform.6. mRNA Vaccine and drug R&D Platform. With these advanced platforms, Yeasen delivers comprehensive customized solutions including enzyme-directed evolution, new enzyme development, enzyme process refinement, and GMP-level scale-up production. These solutions cater to diverse application needs in areas such as in vitro diagnostics, biomedicine, synthetic biology, medical aesthetics, pharmaceutical intermediates, and beyond.

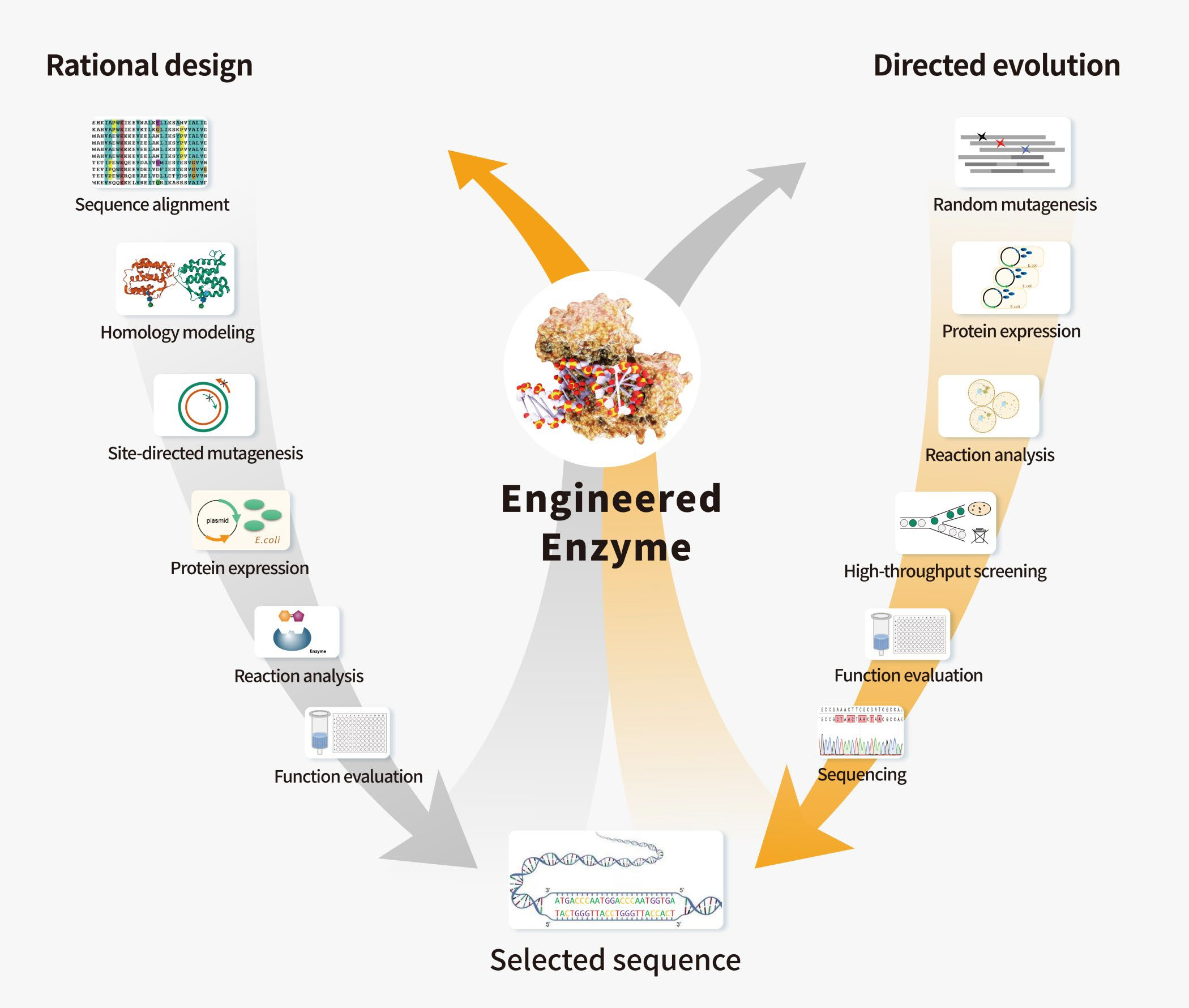

ZymeEditor™ Protein Directed Evolution and Rational Design Platform

We offer a comprehensive suite of solutions with expertise across six key technology platforms encompassing the entire spectrum of enzyme development and production, such as the ZymeEditor Enzyme Evolution Platform, the Multi-host High-efficiency Expression Platform, the Fermentation Process Development Platform, the Purification Process Development Platform, the UCF·ME Ultra-clean Purification Platform, and the Analysis and Quality Control Platform.

Introduction

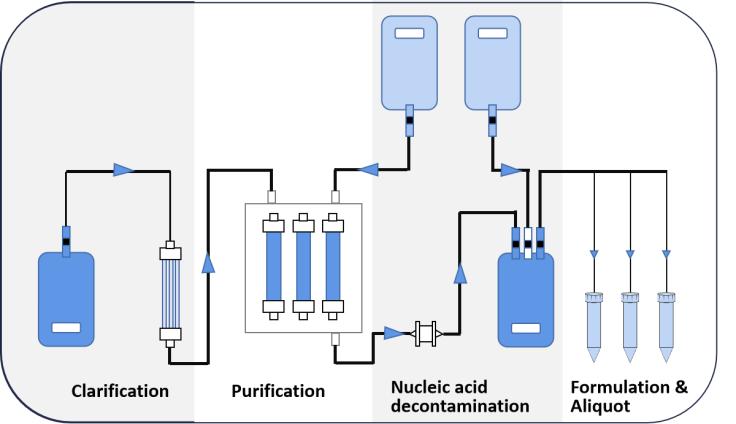

UCF.ME Ultra-clean Protein Purification Platform

We employ a whole purification process using disposable single-use components such as buffer bags, filters, tubes, and chromatography columns. These components are connected by sterile single-use tubes at every stage of production, creating a closed system that prevents exposure to the surrounding environment or operator.

Facility

Recombinant Protein and Antibody Platform

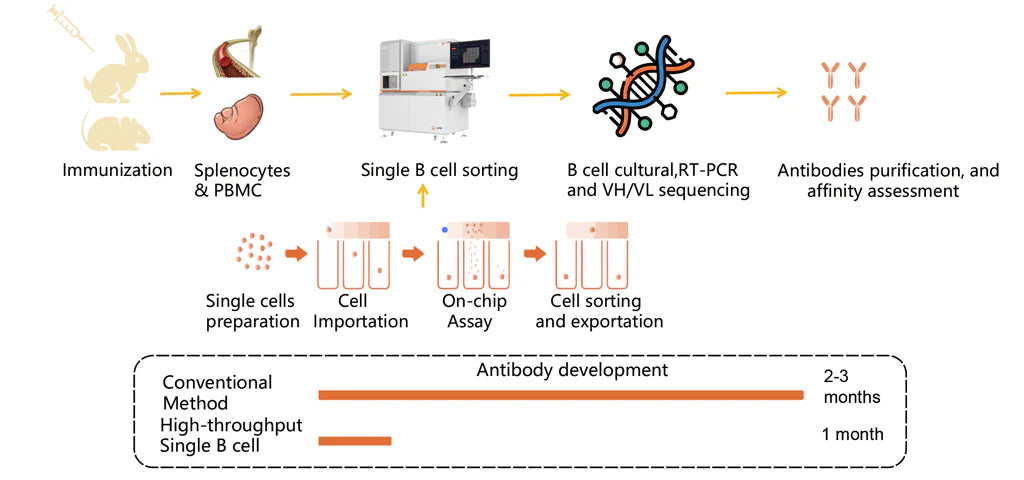

Monoclonal Antibody Platform: Pioneering the Future of Antibody Discovery

- Shortening the antibody discovery time from 4-6 months to 1.5 months.

- Screening more than 14,000 cells simultaneously, ensuring the generation of monoclonal cell lines with a success rate exceeding 99% in just one week.

Lyophilization Platform

We have established a comprehensive Glycerol-free molecular enzyme R&D and Lyophilization platform, and has achieved large-scale production of multiple Glycerol-free molecular enzymes through material selection, environmental control, process optimization, and quality assurance.

Learn more

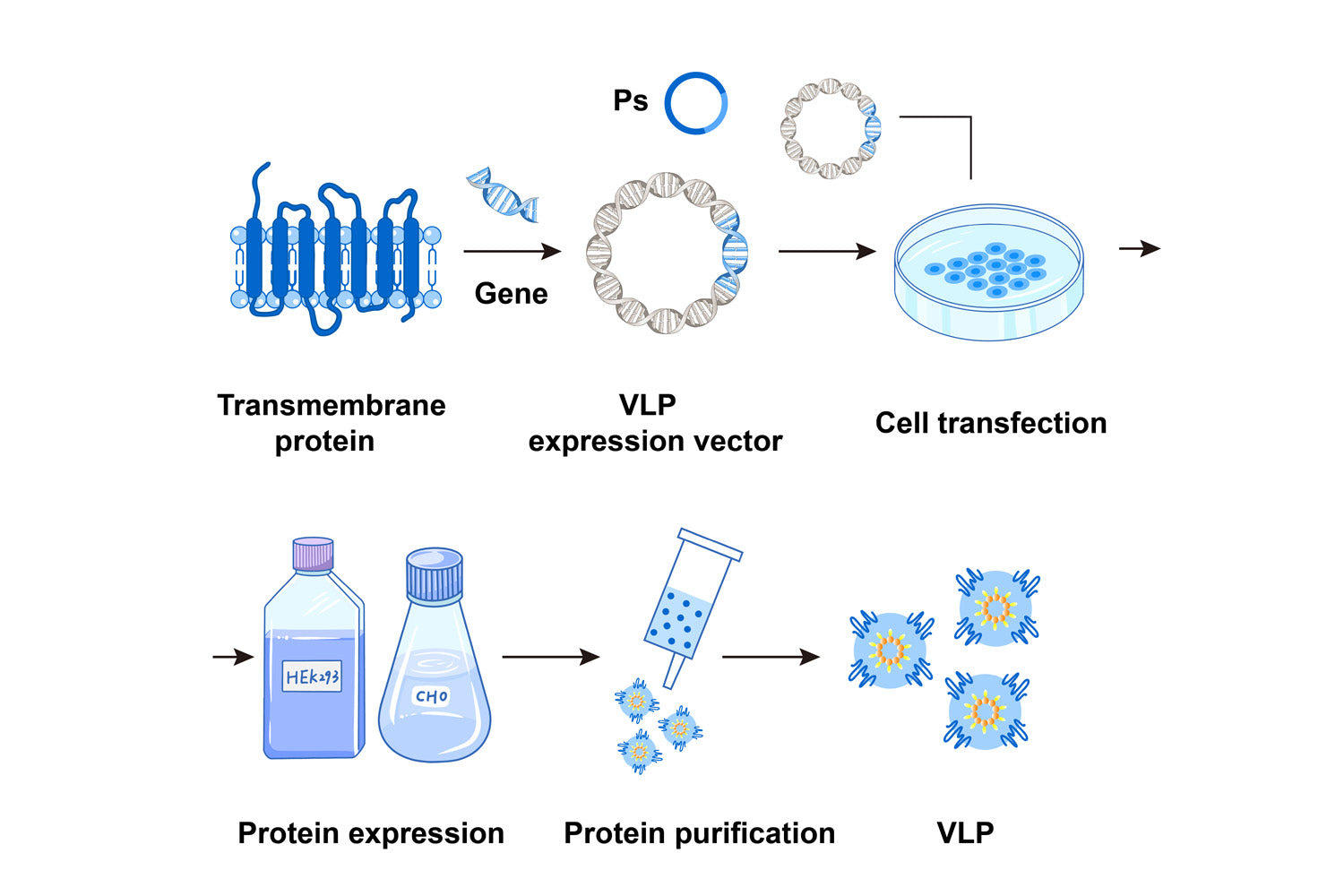

Virus-like particles (VLPs)

High immunogenicity transmembrane proteins for antibody and vaccine development.

Our products