Description

S-Adenosyl methionine (S-Adenosyl methionine, SAM) is an auxiliary substrate involved in the methyl transfer reaction, which in the body is composed of adenosine triphosphate and methionine in the methionine adenosyltransferase under the action of synthesis. SAM is prepared in a solution of 10 mM HCl, 10% Ethanol, and pH 4 at 25℃. This product is produced by GMP process requirements and provided in liquid form.

Features

- Validated, product-specific processes and analytical methods

- Product-specific stability

- Documentation follows applicable GMP guidelines

- AOF production process and raw materials (TSE & BSE)

- Nitrosamine statement

- Regulatory support documents available

- Large-scale production

Applications

- Enzymatic capping process for mRNA vaccines and therapeutics

- Enzymatic methylations of biopolymers

Specifications

| CAS No | 485-80-3 |

| Formula | C15H23N6O5S+ |

| Molecular Weight | 399.44 g/moL |

| Purity (HPLC) | > 90% |

| Content | 32 mM ± 2 mM |

| Composition (1X) | 10 mM HCl, 10% Ethanol pH 4 at 25℃ |

| Structure |  |

Components

| Components No. | Name | 10619ES02 | 10619ES25 | 10619ES50 | 10619ES76 |

| 10619 | S-adenosylmethionine (SAM) GMP-grade (32 mM) | 0.5 mL | 25 mL | 50 mL | 500 mL |

Shipping and Storage

The product is shipped with dry ice and can be stored at -15℃ ~ -25℃ for one year.

Figures

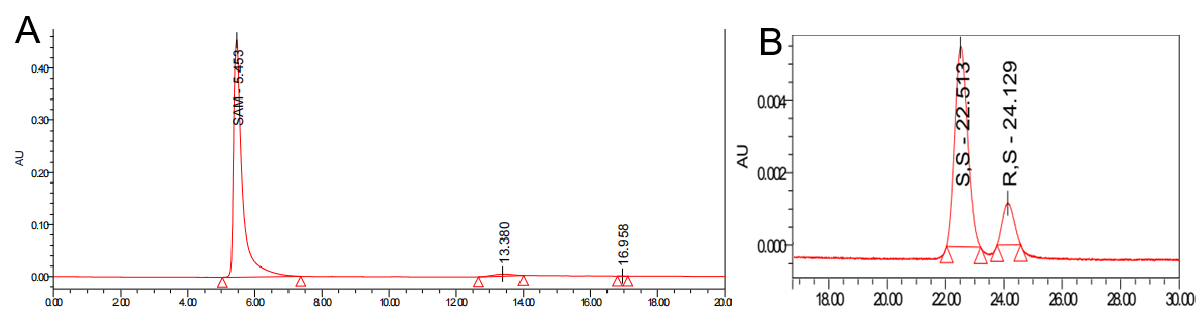

- Purity Assessment

Figure 1. The purity (HPLC) of SAM product could be over 98% (Figure 1A) and the optical purity(ee, %)of (S, S) -SAM isoform always be about 70% (Figure 1B).

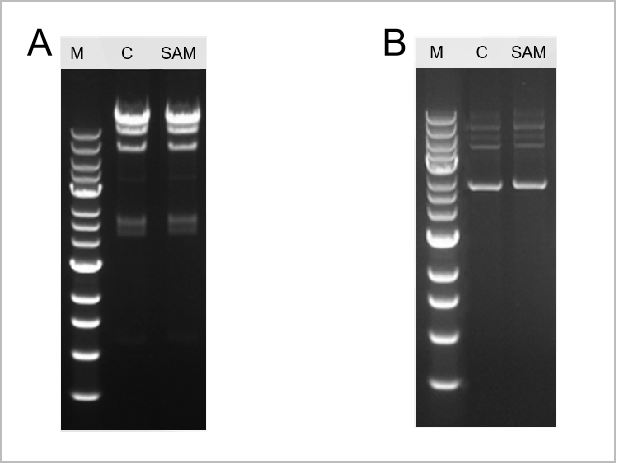

- Enzyme Residual Detection

Figure 2. No enzyme residue was detected by agarose gel electrophoresis.

A 20 µl reaction in the buffer containing 500 ng of Hind III digest of λDNA and 2 µl of S-adenosylmethionine (SAM) incubated for 4 hours at 37ºC results in no difference compared with the control ( SAM free in the reaction system)by agarose gel electrophoresis (Figure 2A). A 20 µl reaction in the buffer containing 500 ng of pUC19 plasmid and 2 µl of S-adenosylmethionine (SAM) incubated for 4 hours at 37ºC results in no difference compared with the control ( SAM free in the reaction system)by agarose gel electrophoresis (Figure 2B).

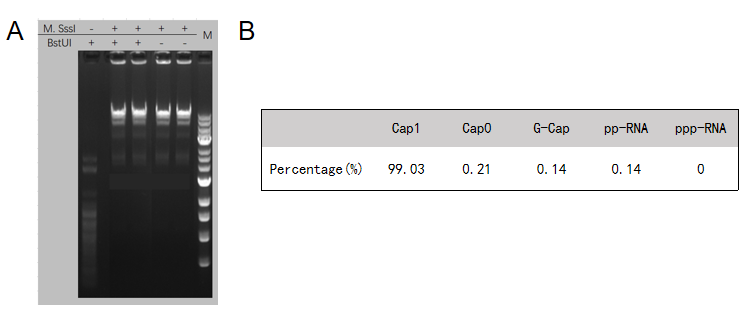

- Functional Test and Verification

Figure 3 The capping efficiency of YEASEN post-transcriptional capping reaction could be close to 99%.

A 20 µl reaction in the buffer containing 1 µg of λDNA, 1 unit of M. SssI (CpG Methyltransferase), and 160 µM S-adenosylmethionine (SAM) is incubated for 1 hour at 37°C. The resulting DNA is resistant to digestion with BstUI as determined by agarose gel electrophoresis (Figure 3A). 10 μg RNAs were denatured by incubation at 65°C for 5 min before capping. A 20 μL post-transcriptional capping reaction was set up and incubated at 37°C for 2 hours in a PCR machine. Transcripts were purified by magnetic beads (Cat#12602). Then the capping efficiency is detected by LC-MS (Figure 3B).

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Inquiry

You may also like

FAQ

The product is for research purposes only and is not intended for therapeutic or diagnostic use in humans or animals. Products and content are protected by patents, trademarks, and copyrights owned by Yeasen Biotechnology. Trademark symbols indicate the country of origin, not necessarily registration in all regions.

Certain applications may require additional third-party intellectual property rights.

Yeasen is dedicated to ethical science, believing our research should address critical questions while ensuring safety and ethical standards.